Who said that a sensor IoT made no sense? Some devices fully rely on sensory capabilities to support manufacturers in their automation needs and increase their performance. Using the five senses in IoT is nothing new (read our article Machines become human thanks to these technos imitating the 5 senses) but interest is growing since the resumption of activity following the health crisis. “The demand for human-machine interfaces (HMI) is intensifying because manufacturers need to automate their processes,” observes Anna Pugach, co-founder of the Bordeaux start-up. Touch Sensity, specialized in haptics (sense of touch). In the design of these HMIs, it is relevant to resort to biomimicry, because this engineering method allows rapid developments. “

A keen vision

Of the five senses, sight is the most widely used in industry. The reason: “This organ is the easiest to study and our biological system is at the same time very fast and very efficient”, underlines Luca Verre, co-founder and CEO of the start-up. Prophesee, which markets a camera based on human vision that only records movement. Result: only the events are broadcast, saving the sending of unnecessary data to view. Based on the functioning of an artificial retina, Prophesee is able to shoot at 10,000 frames per second while consuming less than 10mW. In the logistics, where the need for automation is accelerating, eye-tracking is popular and vision is developing more and more in robotics, “because customers want more human interactions”. As proof of this interest, Sony has joined forces with Prophesee to co-develop two types of vision sensors for industrial equipment.

A delicate touch

In robotics, to increase machine performance, Luca Verre observes a new trend, that of associating sight with touch. An orientation confirmed by Anna Pugach, at Touch Sensity, who started her activity to give the sense of touch to robots. “The interest is evident in predictive maintenance. Manufacturers can no longer afford to suffer breakdowns and with touch, there is no longer any need to place a sensor in a critical area to detect an anomaly on an ad hoc basis. The materials indicate in real time if they are damaged, ”explains Mehdi El Hafed Pocard, co-founder of Touch Sensity, which works on these subjects in aeronautics. Beyond industry, other sectors can benefit from touch. “We have a card to play in textiles to make the fabric sensitive and to collect data on the movements of the body.”

Fine hearing

In factories, if robots are too sensitive to waves, or if sensors are disturbed in indoor geolocation by too many devices, the alternative is hearing, using ultrasound. “This wave, which the ear does not hear but the body perceives, is universal and cannot be hacked, strong arguments in the IoT”, highlights Emmanuel Ruiz, CEO and founder of the French company CopSonic. However, since the resumption of activity, the sector in which acoustic IoT has the most advantages is contactless. His interest ? “Send commands to connected buttons without touching them”, for example in elevators.

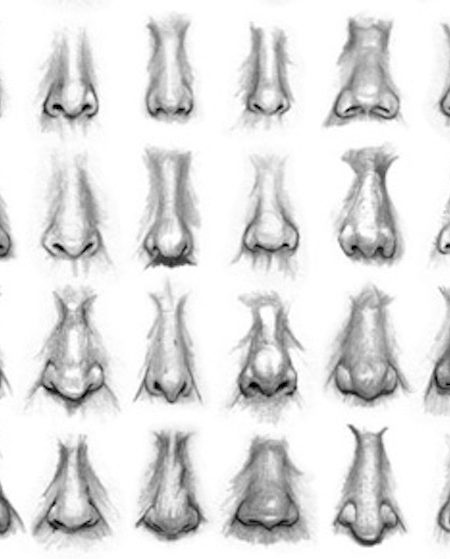

The hollow nose

The sensors analyze the molecules to determine odors by AI. © Microsoft

Smell is also benefiting from the health crisis, by making it possible to detect bad odors in a building. Air quality has become the third major use of IoT sensors in 2021, according to the Revelations IoT 360 study, presented in October at IoT World. It was also during confinement that Benjamin Cabé, principal program manager at Microsoft, developed an artificial nose with artificial intelligence, which could allow many professional applications by connecting it to a set of objects via Azure IoT. . “To have an artificial nose, it is enough to use several retro-olfaction sensors in the hardware (4 gas sensors were used). On the other hand, for it to work, the important thing is not to neglect the learning stage with good databases so that the AI makes the correlations between molecules “, confides Benjamin Cabé, who also puts forward the combination of the senses to offer innovative offers to manufacturers.

A sure taste!

The artificial language was developed in 2000. © Sofiane Bensizerara / Alpha MOS

A position also adopted by Alpha MOS, a French company specializing in sensory analysis solutions, which first designed an electronic nose in 1993 before developing a taste sensor in 2000 with Astrée, its electronic tongue. The main need is in the food industry. “Consumers frequently change their tastes and manufacturers cannot keep pace with new products by relying on testers to try products. IoT allows, thanks to sensory analysis, to cut production cycles in half”, explains Pierre Sbabo, CEO of Alpha MOS. The company, which works with a European dairy giant, is seeing strong demand in quality control. “The players find it difficult to recruit, they are obliged to automate their processes and the IoT contributes to it”, remarks Pierre Sbabo before concluding: “Building sensory models reassures manufacturers because it makes it possible to obtain results similar to those of the collaborators, who will always remain at the verification stage in the factories. “

Source: Taste, smell, hearing … IoT takes on all these senses – The Times Hub

Various multisensory trends

Scent adds more dimension to exhibits and stories & enhance perception and interaction | Denver Art Museum

Why Clinique’s Next Move In The Metaverse Is A Winning Formula For Web3 Retail | Forbes

How to Use the 5 Senses — Plus a Secret 6th One — to Catapult Your Brand Experience | MarketBeat

Art made from mushroom foam, walnut ink and more featured in Sustainable Studios exhibit | lancasteronline.com

love hultén’s CHD-4 drum machine turns patients’ heartbeats into rhythmic soundscapes | Designboom