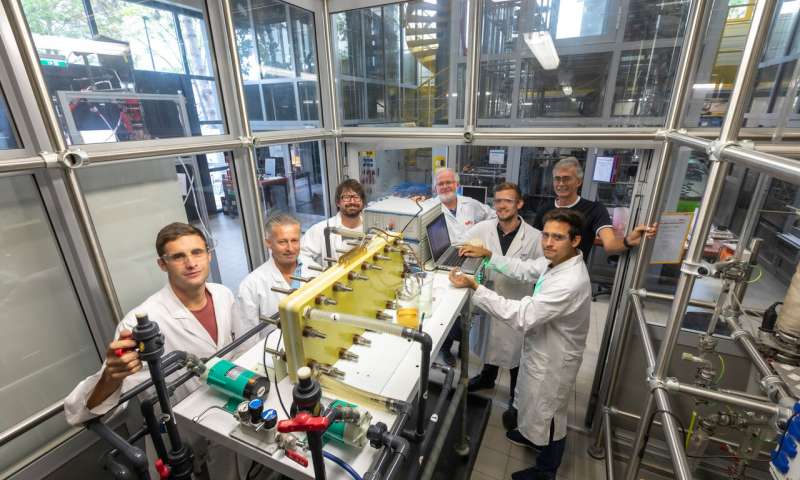

TU Graz researcher Stefan Spirk has found a way to replace liquid electrolytes in redox flow batteries by vanillin. Credit: Lunghammer – TU Graz

Researchers at TU Graz have found a way to convert the aromatic substance vanillin into a redox-active electrolyte material for liquid batteries. The technology is an important step toward ecologically sustainable energy storage.

“It is groundbreaking in the field of sustainable energy storage technology,” says Stefan Spirk from the Institute of Bioproducts and Paper Technology at Graz University of Technology. He and his team have succeeded in making redox-flow batteries more environmentally friendly by replacing their core element, the liquid electrolyte, which are mostly made up of ecologically harmful heavy metals or rare earths—with vanillin, an important ingredient of Austrian vanilla croissants.

Sustainable energy storage

Vanillin, a commonly used flavor compound, is one of the few fine chemicals produced from lignin. Spirk and his team refine lignin into vanillin into a redox-active material using mild and green chemistry without the use of toxic and expensive metal catalysts, so that it can be used in flow batteries. The process works at room temperature and can be implemented with common household chemicals. Vanillin is also present in large quantities. “If you want, you can even buy it in the supermarket, but we can also use a simple reaction to separate it from lignin, which in turn is produced in large quantities as waste product in paper production.”

Patenting and commercialisation

The separation and refining process was patented and the successful test results were published in the journal Angewandte Chemie International Edition.

Now the researchers want to commercialize the technology, especially since the process is highly scalable and suitable for continuous production. Spirk explains: “The plan is to hook up our plant to a pulp mill and isolate the vanillin from the lignin that is left over as waste. Whatever is not needed can subsequently flow back into the regular cycle and be used energetically as usual. We are in concrete talks with Mondi AG, a leading global manufacturer of paper-based products, which is showing great interest in the technology.” For the final implementation, the technology has to be tested in real operation. The company is now looking for energy supply companies that can integrate the start-up’s redox flow technology into its infrastructure and thus relieve the burden on the grid. Spirk is convinced of its future success because: “We can keep the value chain ranging from the procurement of raw materials and components to the generation of electricity on a regional basis, enable storage capacities of up to hundreds of MWh, relieve the strain on the electricity grid and make an important contribution to the green energy storage.”

Tests at TU Graz with a 3 kilowatt hour prototype and with vanillin-based electrolytes proved the effectiveness of the new process. Credit: Lunghammer – TU Graz